VTG Connect

By capturing valuable data about your fleet and all your transports, VTG Connect lays the foundation for efficient digital fleet management.

Optimize your rail transports with VTG Connect

Precise real-time data is essential for efficient rail freight management. With VTG Connect, you stay continuously connected to your freight wagons and tank containers along the entire transport chain and can capture valuable telematics data.

Our telematics technology combines telecommunications and IT to create a robust digital infrastructure for your rail transports. With tracking and tracing, you can monitor your equipment at all times. Additionally, acceleration sensors detect shock events, while temperature sensors track ambient conditions to identify potential cargo or equipment damage early on.

VTG Connect – Pioneering digital rail logistics

As early as 2016, we took the lead in digitalizing rail freight with VTG Connect, making a significant step toward smart mobility and expanding our service portfolio. Today, this innovative solution provides a comprehensive digital data foundation, accessible via our customer platform traigo or directly in your own system.

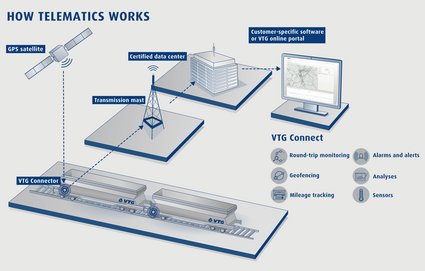

How telematics works

The VTG Connector is the core component of our intelligent telematics system for rail freight transport. Ideally installed on the I-beam of freight wagons, it operates autonomously with a solar-powered battery.

Real-time location tracking via GNSS (Global Navigation Satellite System)

Automated data transmission every six minutes via mobile communication during movement-

Business-relevant insights available through traigo or ITSS-1 data interface -

End-to-end encrypted data transfer using AES 128/256 for maximum security -

ISO 27001-compliant data hosting and storage for top-tier IT security standards

With VTG Connect, you gain a reliable, secure, and transparent digital rail fleet management solution – ensuring efficient and connected rail logistics

Features of the VTG Connector device

Device specifications | Power supply | Data processing |

|---|---|---|

ATEX Zone 1-certified acceleration sensors to detect impacts or shocks along three-dimensional axes | Energy harvesting for autonomous operation | Encrypted data transfer in accordance with AES 128/256 |

| Temperature sensor to measure the ambient temperature | Lithium-ion battery | Data hosting and storage in accordance with ISO 27001 |

Position and velocity determination via GPS/QZSS, GLONASS, Galileo, BeiDou and GSM triangulation in cases where GNSS positioning is not possible | Intelligent algorithms to minimize power consumption and adapt the device to environmental conditions | Data forwarding via an ITSS1 standard interface |

Wireless connectivity to external devices and sensors via WPAN IEEE 802.15.4 2.4-GHz band for product monitoring and to support operating processes | ||

| Maintenance-free device | ||

| Alarm functions – A trigger engine facilitates alerts in response to unforeseen transport events | ||

Geofencing – Definition of point of interest (PoI) zones and geozones: Notifications are sent automatically when a wagon enters or leaves these zones |

ATEX certifications for the VTG Connector

As of 2017, VTG has also been fitting hazardous goods wagons with the VTG Connector on. The corresponding certificates and documents can be found here:

Sensors

Better planning and increased efficiency: Sensors keep you informed of the status of your freight wagons and consignments at all times.

Smart sensor technology for maximum efficiency in rail freight

A combination of state-of-the-art sensors and telematics provides you with real-time data on your rail freight operations. With this information, you can immediately react to disruptions and proactively monitor freight wagons, tank containers, and cargo—preventing damage before it occurs.

Our advanced sensor solutions, including the kingpin sensor and temperature sensor, enhance operational efficiency and ensure greater transparency in rail logistics.

VTG: Driving innovation in rail freight technology

As a leader in rail freight innovation, VTG continuously explores new applications for digital sensor technology. We are currently developing cutting-edge solutions such as automated brake testing and smart load detection—delivering smarter, more efficient transport processes.

Your benefits at a glance:

- Real-time data for maximum transparency and fast decision-making

- Optimized fleet performance with early detection of potential disruptions

- Increased efficiency through the automation of manual processes

- Instant alerts for irregularities, preventing delays and damage

With VTG Connect Sensor Technology, you enhance the efficiency, safety, and digitalization of your rail freight operations—ensuring seamless, data-driven logistics.